Application in the paper industry

In the pulp and paper industry, caking, bridging and blockages in ovens, containers, reactors or silos are one of the most common causes of efficiency losses and production interruptions.

To remove these blockages, downtimes of many hours, if not several days, can occur.

the advantage

By using our ATD-Pressure Gas System while operation, these long cooling phases, which are necessary to allow personnel and machines to work in the oven, can be avoided.

By properly installing the ATD-Pressure Gas Tube into ATD-Base Socket located on the kiln shell, the tube blasts CO2 inside destroying build-up, while leaving the brick lining intact.

less time required

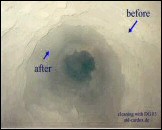

Compared to the conventional method, the use of the ATD-System is quick efficient and cost-saving. In six to eight hours, the ATD-System can remove a buildup of 10 meters without even sending one man into the kiln.

Typical applications in the pulp and paper industry

| Lime kilns and cyclones: | Removal of ring incrustations and solid residues in the recovery circuit |

| Fiber silos and waste paper bunkers: | Dissolution of bridging and material blockages |

| Flue gas pipes and dryer systems: | Removal of incrustations and caking caused by resins, fibers or dust |