Target Blaster®

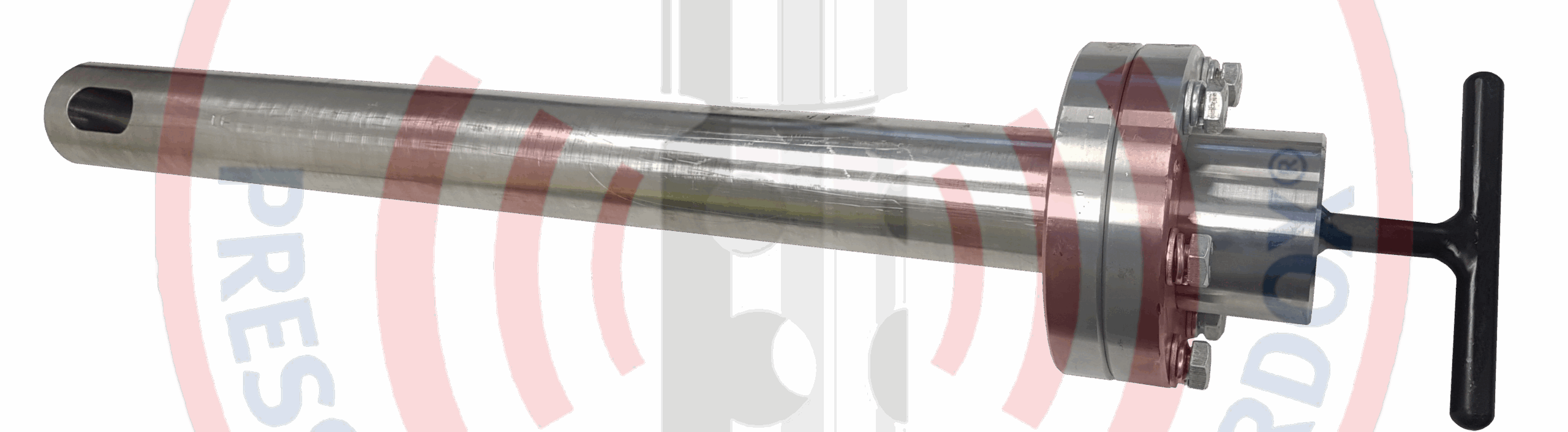

Our ATD-Target Blaster is a high-pressure nozzle made of heat and chemical resistant steel. It can be installed in the critical area during the production process and remains in position, ready to perform its function. The lengths and Dischargenozzles are individual and customized.

Even a straight discharge is possible by offering a 100% safe locking of the ATD-Tube during blasting.

Description

The patented ATD-Target Blaster is a high-pressure nozzle made of heat and chemical resistant steel. It can be installed in the critical area during the production process and remains in position, ready to perform its function.

The length, and therefore the insertion depth, of the Target Blaster, as well as the type of the discharge openings, are adapted in order to fully meet efficiency and safety requirements for the application. Even a straight discharge is possible by offering a 100% safe locking of the ATD-Tube during blasting.

Outside the plant, access to the ATD-Target Blaster is via a high-capacity thread. It is designed and engineered to ensure easy functionality and fully strengthened to reliably handle the existing traverse forces of the activated ATD-Tubes. Before and after use, the thread is protected and closed by a plug.

When ready for action, the ATD-Pressure Gas Tube is screwed to the ATD-Target Blaster by hand.

The existing installations in the cement industry are mainly in the critical areas of the kiln inlet chute and close to the entry of secondary fuel components, such as the tyre chute.