the ATD-Pressure Gas System CARDOX in Detail

Equipment and Application:

ATD is offering autarkical working Systems that make the trained operators of each plant working independently and flexible whenever necessary. For practical application of the System, the following items are required:

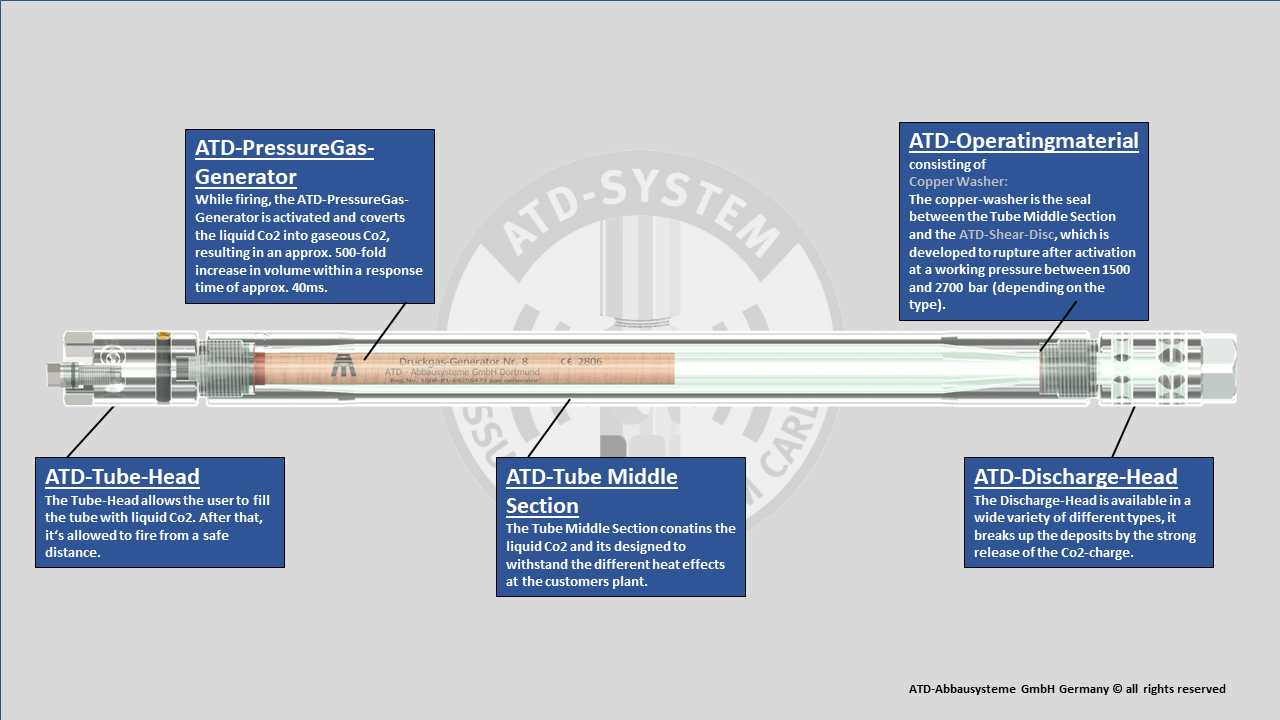

ATD-Pressuregas Tube

The principle of the procedure.

- Tube Head

- Tube Middle Section

- Discharge Head

ATD-Operating Material

For activation of the DG Tube.

- ATD Generator

- Copper Washer

- Shear Disc

ATD-Lockings

For safe mounting of the DG Tube.

- ATD Base Socket

- ATD Grip Case

- ATD Safety Clasp

ATD-Priming Equipment

For controlled activation of the DG Tubes.

- Priming Machine

- Safety Circuit Tester

- Firing Cable

ATD-Drilling Equipment

For production of necessary boreholes.

- Rock Drill

- Drill Rod

- Drill Guide

ATD-Filling Equipment

For filling the DG Tubes with CO₂.

- Filling Pumps

- High Pressure Valves & Lines

- External CO₂ Steel Bottle

ATD-Cardox Room

All in one place.

- Central location for all ATD equipment

- ATD-Caddy for transportation

- Wall-mounted rack for tube storage

Industries for ATD-CARDOX

🔍 learn moreImportant advantages of the ATD-System for these applications:

- ATD-Pressure Gas Tubes are used as “ready for action” charges. They are safe to handle and transport

- ATD-Pressure Gas Tubes work with cold CO2 gas. It is therefore, considered safe to use in the presence of flammable gases.

- The ATD-Pressure Gas System is especially suited and approved for loosening ammoniated compound granulas fertilizer

- ATD-Pressure Gas Tubes offer a high rock-breaking capacity while reducing the amount of dust and loose fragments

How its been used

The ATD-Pressure Gas Tube is been used directly where the build-up occurs. As the entry to the obstruction, ATD-Base sockets are installed i.e. on the steel shell of the plant. Through the insertion hole, the ATD-Pressure Gas Tube will be inserted into the build-up with the Discharge Head in safe distance behind the refractory.

Locked with the ATD-Grip Case to the ATD-Basesocket, the DG-Tube is set to break up the deposits by the strong release of the CO2-charge.

Inside the ATD-Pressure Gas Tube, the pressure of the CO2 charge gets consequent increased by activating the ATD-Pressure Gas Generator. At a very pre-determined level, the Shear Disc blows and the released CO2-gas is directed by the Discharge Head exactly where required.

With application 150 – 600 litres CO2 volume with blasting pressures between 1500 and 2700 bar are set free, depending upon used ATD-Pressure Gas Tube. The response time amounts to approx. 40 ms.

There are 7 different type of Pressure Gas Tubes with different achievements and dimensions for the individual requirements available.

Your staff will be trained and certified by ATD-Technicians in the ATD-PressureGasSystem CARDOX.

Safe, Reliable & Sustainable

CO₂ instead of explosives

No blasting license required

safe to use and reusable

Effective & Gentle

High refractivity

Quickly ready for use

Precise discharge

Quality & Innovation

7 Tubetypes available

Continuous development

active since the 50s